Engineered to keep your production line moving smoothly.

At Form Plastics, we design and manufacture precision Lidding and Sealing Equipment — and the support equipment that keeps them performing at their best. Our comprehensive line of support equipment enhances efficiency, consistency and throughput, helping you get the most out of your packaging operations.

Each unit integrates seamlessly with Form Plastics Lidding and Sealing Equipment, providing a complete end-to-end solution that minimizes downtime and optimizes workflow.

| Length | Width | Height |

|---|---|---|

| 31 1/2" Diameter | 29" - 30" Adjustable |

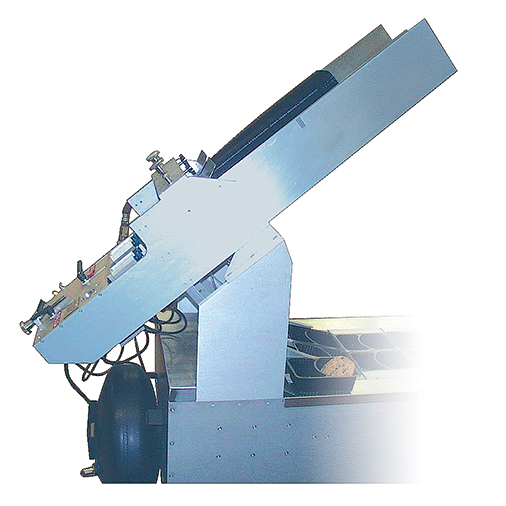

The LS100 accumulator is designed to increase productivity through the efficient handling of the finished product, without interrupting the continuous lidding process. Construction highlights include totally enclosed stainless steel, swivel & locking casters, and a variable speed motor.

| Length | Width | Height |

|---|---|---|

| 6' | 24" | Adjustable |

This sturdy and functional worktable has swivel casters with brakes, allowing for complete mobility of lidding equipment and supplies. It is equipped with a racking module that can hold up to 12 sealing plates or tray holders and a plastic top shelf cover.

| Length | Width | Height |

|---|---|---|

| 12′ | 16" | 32" |

The FPBC120 inline belted conveyor is equipped with a variable speed control, 12″ wide belt, and a photo-optic sensor that helps control production flow.

| Placement | Integrated |

|---|---|

| Mounted on Machine | Fully with HHA600 |

The vacuum tray denester is constructed of anodized aluminum with stainless steel hoppers. The vacuum tray denester automatically denests empty trays onto the conveyor line and can accommodate either dual or single lane conveyors

| Placement | Height |

|---|---|

| Standalone | Adjustable |

Also known as a screw denester, the Mechanical Denester automatically denests trays onto the conveyor line by utilizing rotating screws, and is a fully adjustable, stand-alone denester, constructed of stainless steel with a servo motor and speed adjustments.

| Configuration | Operations | Spouts |

|---|---|---|

| Customizable | Fully Automated | Single / Multiple |

Our portable, power filler units assure fast, precise, dripless dispensing of viscous product, cutting meal assembly time and reducing food waste. All filler units dispense using a variety of different accessories and custom spout configurations.

Why choose Form Plastics support equipment?

• Designed and manufactured in the USA.

• Reliable and durable machines – engineered for long-term performance in high-demand environments.

• Seamless integration – compatible with Form Plastics tray sealing equipment

• Engineered for efficiency, reliability, and long service life

• Expert support and maintenance – ongoing technical assistance to keep your equipment running smoothly.

Optimize your production line

Whether you’re upgrading your current system or designing a new production line, Form Plastics support equipment delivers the performance and reliability your operation demands.

Let us help you choose the best sealing solution for your food service operation. Contact us today for more information or a quote!